SEW Eurodrive company visit “SEW underway to a circular supply chain”

This article is based on the contribution of a group of APICS supply chain specialists trained by Visie Partners, complemented with general observation and analysis.

With a group of supply chain professionals, we visited SEW Eurodrive in Rotterdam. SEW has implemented lean production techniques, allowing short delivery times for its customers. The drives are assembled to customer configuration. A workforce of cross-trained employees can achieve short delivery times. Since its commitment to lean about 20 years ago, SEW has continuously improved its performance. SEW management is a lean advocate and actively shares its experience with other companies.

SEW Eurodrive has remanufactured their customers' electro engines (drives) for a few years. After the quoted price has been accepted by the customer and the product is received at SEW, the product is dismantled and rebuilt with new parts replacing the worn components. The customer gets a drive as good as a new one with the same warranty as a new product.

The takeaway from the discussion is that a circular supply chain requires a focus on the sustainability needs of the customer, starting with the customer's value profile and the supplier's value proposition. For the value proposition, it is essential to assess future trends like technology, legislation on renewable materials, and customer priorities. The value proposition should be based on a business case where cost and benefits from environmental and social, and economic perspectives should be considered.

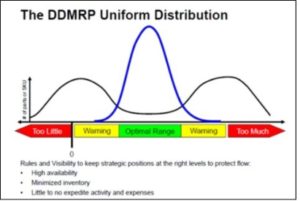

Using standard definitions for processes and metrics allows for efficient supply chain-wide implementation. In 2022 the SCOR DS framework for supply chain processes, metrics, practices, and required people skills are aligned with modern supply chain requirements. The SCOR framework now includes environmental and social sustainability performance metrics linked with alternative sustainability best practices. The practices and performance metrics relate to processes, activities, and possible workflows. Organizations can pick the relevant workflow elements to assemble their supply chain processes.

Implementing sustainability in supply chains requires curiosity, enthusiasm, collaboration, commitment, and the right implementation tools.